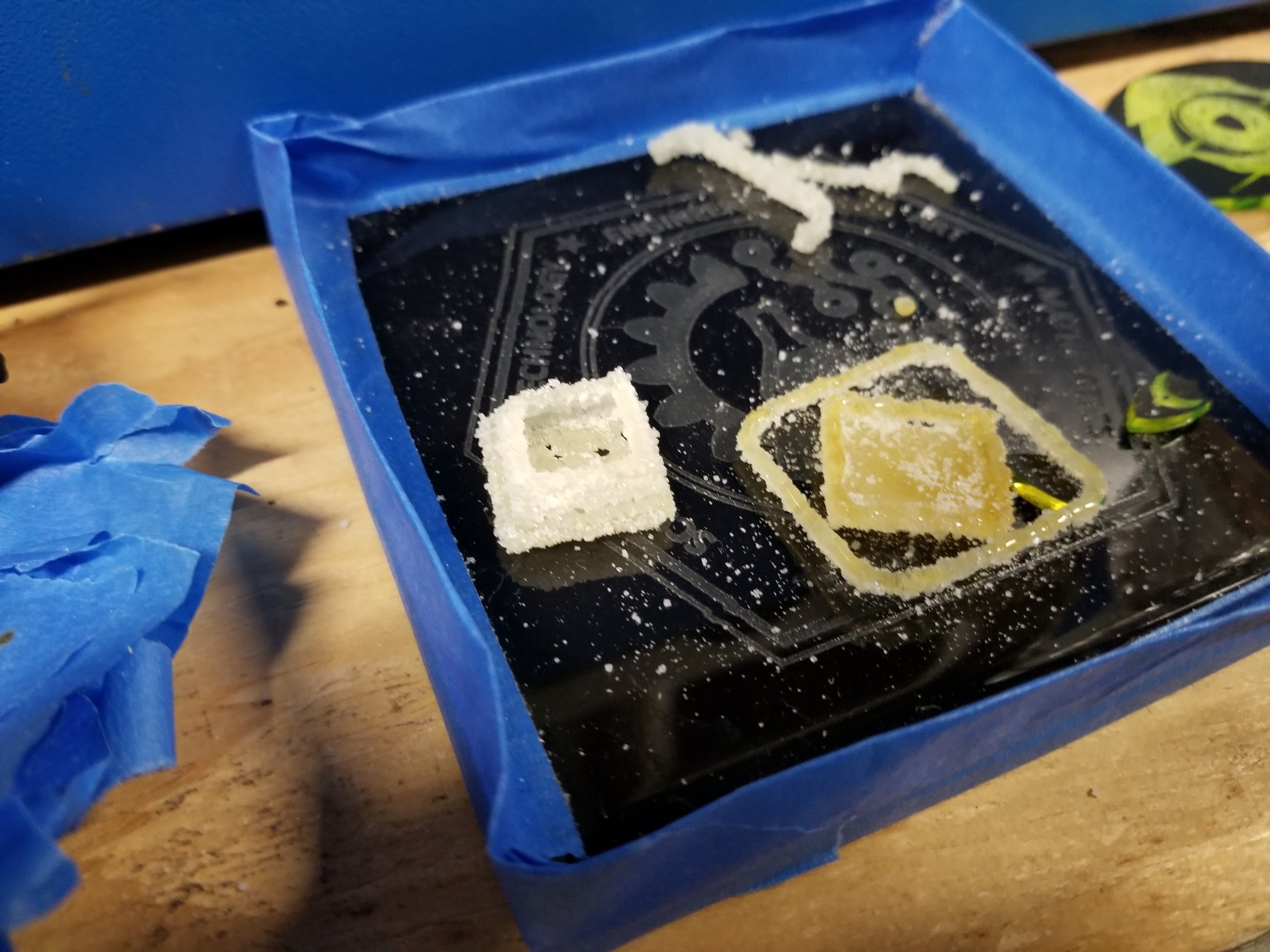

The bed then continues to lower until every layer is built and the part is complete. After one layer is built, the bed lowers and another layer is built on top of the existing layers. The laser traces the pattern of each cross-section of the 3D design onto a bed of powder.

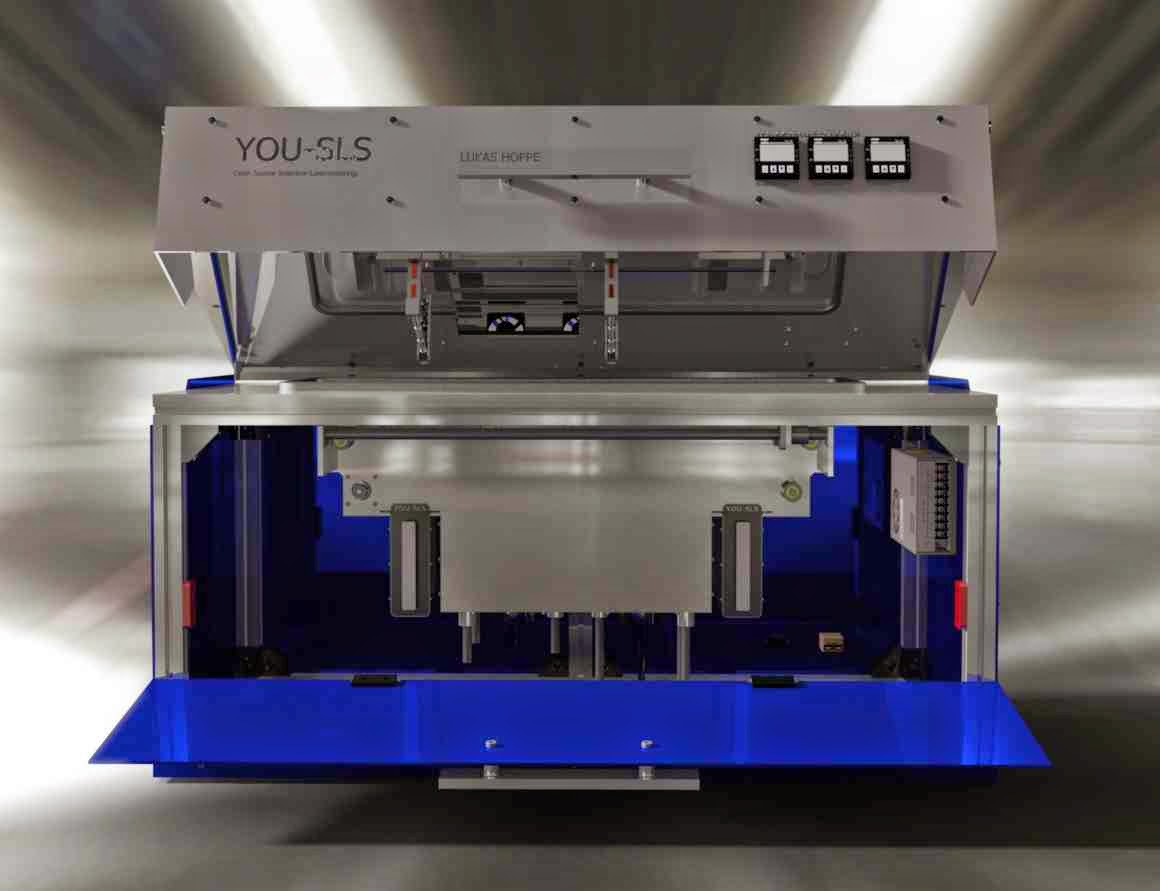

The highly precise SLS process uses a laser to fuse particles of plastic, glass, ceramic or metal. Like other additive manufacturing printers, the 3D Systems ProX 500 SLS printer builds products layer by layer. “We’re already thinking of other ways to use this technology with new applications.” “3D printing has allowed us to develop new products and get them to market in a fraction of the time it took using traditional machining,” says Alan Bradshaw, company co-CEO. Food-forming pistons are produced on the 3D printer from a food-grade nylon and integrated into production equipment sold to customers around the world. Idaho Falls, ID, (September 9, 2015)-Idaho Steel, a manufacturer of food processing equipment, has embraced 3D printing with the purchase of a 3D Systems Selective Laser Sintering (SLS) machine. Intermountain 3D and Idaho Steel Announce InstallatioĪlign=”center”> Intermountain 3D and Idaho Steel Announce Installation of Production SLS 3D PrinterĪlign=”center”> First of its kind printer in Idaho brings new manufacturing capability to Idaho Steel

0 kommentar(er)

0 kommentar(er)